Compression Spring Wires

Product Details:

- Material Steel

- Product Type Spring Wire

- Application Industrial

- Grade 304

- Surface Galvanized

- Standard ASTM

- Click to view more

X

Compression Spring Wires Price and Quantity

- 200 Kilograms

Compression Spring Wires Specification

- Spring Wire

- Industrial

- ASTM

- Galvanized

- 304

- Steel

Compression Spring Wires Trade Information

- 1200 Kilograms Per Day

- 15 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- As per buyer requirement

- All India

- ISO 9001:2008, ISO 14001:2007, OHSAS 18001:2001

Product Description

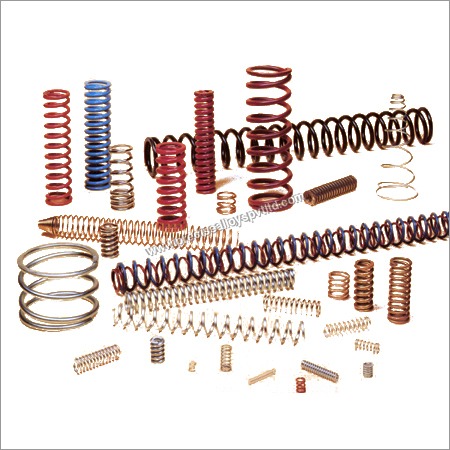

Owing to our rich industrial expertise and skills, we are renowned as one of the most profound manufacturers and suppliers of Compression Spring Wire. These are engineered using standard quality raw materials. As per the clients specifications, these are offered in different size tolerances and weights. The wires are more flexible and are known for their corrosion resistance and supreme quality feature. This wire is available at reasonable prices. We also offer the customization of wires.

Offered spring wires have maximum 10 mm dimension. Based on application type, these are offered with chrome plated or nickel or zinc plated surface. These wires have closed or open end design. Materials like alloy steel, stainless steel, nickel plated high carbon steel or other fine quality metal has been used to design such wires. These are used as essential parts of furniture, automobiles and industrial equipments. Application of such wires can also be noticed in the design of toys, electronic items, motorcycles, power instruments, etc. These have single or double loops based design. Advanced CNC or stamping technology has been followed to design such wires. Standard of these products has been checked on the basis of their compressive force, design, raw material selection, surface finish, dimension, strength and longevity. These are light in weight and are highly durable. Standard of such products has been checked on the basis of their dimension, weight, longevity, compressive force, service life, surface finish and strength. Design and manufacturing method of such springs conforms to global norms. These can be availed in standard and tailor made specifications.

Application area of Compression Spring Wires:

These springs have wide usage in telecommunication, automobile, furniture making, craft items designing, lamps and lanterns making, vacuum cleaner production and sports equipments production arena.

Special attributes of Compression Spring Wires:

1. Utilization of CNC technology

2. Metal plated surface with corrosion proof design

3. Less weight and reasonable price

4. High compressive force

High-Quality Galvanized Compression Spring Wires

Our galvanized compression spring wires, made from ASTM-certified steel grade 304, provide outstanding protection against corrosion. Their adaptability makes them suitable for demanding industrial environments, ensuring longevity and consistent performance. By choosing products that meet international standards, users benefit from peace of mind and operational reliability.

Comprehensive Industrial Applications

These spring wires are widely used in sectors such as automotive, machinery, electronics, and general engineering. Quality manufacturing processes make them ideal for high-stress roles, ensuring efficient energy absorption and return within assemblies. Our products are available across India and serve global clients through established export and import networks.

FAQs of Compression Spring Wires:

Q: How are compression spring wires manufactured to meet ASTM standards?

A: Compression spring wires are produced using advanced processes that adhere strictly to ASTM standards. Grade 304 steel is selected for its strength and corrosion resistance, and the wires are galvanized to enhance durability. Rigorous quality checks ensure all products deliver consistent, reliable performance for industrial use.Q: What industrial applications commonly use galvanized compression spring wires?

A: Galvanized compression spring wires are essential in applications such as automotive assemblies, industrial machinery, electronics, and equipment manufacturing. Their resilience, flexibility, and corrosion resistance make them suitable for environments where operational stability and longevity are critical.Q: When should you choose 304 grade steel compression spring wires for your project?

A: You should opt for 304 grade steel compression spring wires when your project requires high corrosion resistance, durability under stress, and conformity to ASTM standards. They are particularly valuable in outdoor or chemically exposed industrial environments.Q: Where can I source high-quality compression spring wires in India?

A: High-quality compression spring wires can be sourced from reputable Indian manufacturers, suppliers, and exporters who comply with ASTM standards. Many operate both domestically and internationally, ensuring a reliable and consistent supply chain.Q: What is the benefit of using galvanized surface treatment on compression spring wires?

A: The galvanized coating offers superior protection against corrosion, extending the lifespan of compression spring wires and reducing maintenance needs. This ensures long-term, cost-effective operation, especially in harsh industrial conditions.Q: How do these wires enhance the efficiency of industrial equipment?

A: Compression spring wires absorb and release energy efficiently, helping machinery maintain steady operation and minimizing wear and tear. Their galvanization and high-grade material contribute to fewer breakdowns and greater process reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wire for Springs' category

|

PRECISE ALLOYS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese