Filter Bag Cage Wire

35 INR/Kilograms

Product Details:

X

Filter Bag Cage Wire Price And Quantity

- 35 INR/Kilograms

- 1 Kilograms

Filter Bag Cage Wire Trade Information

- 1200 Kilograms Per Day

- 10 Days

Product Description

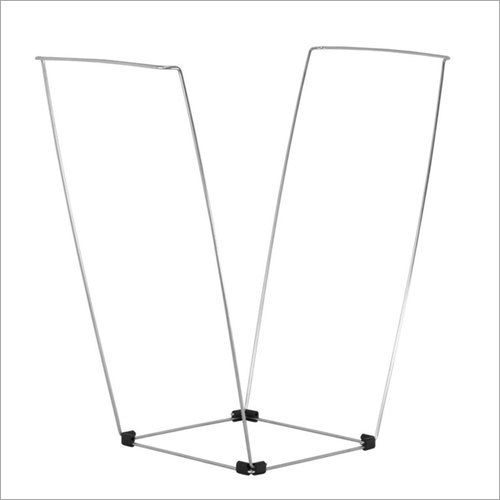

Galvanized steel made Filter Bag Cage Wires are totally corrosion and wear proof. Advanced galvanization technology has been followed to weld such wires in order to prevent their abrasion. Special surface treatment of such wires extends their service life. Application of such cage wires can be noticed in chemical processing, metallurgy and also in other industries. Strong and sturdy construction, reasonable price, ergonomic appearance and light weight are the key aspects of these wires. We offer these wires at reasonable price.

The Filter Bag Cage Wire is the highly strong support that is extremely lightweight and thus ensures simplicity in installation and upkeep. It can meet all the requirements such as tightness, uprightness and smoothness. This coop ensures improved operation, enhanced capacity, less emissions and negligible electricity. This is made to give support to the shape of dust collector bags and ensuring the prevention from collapsing. These wires can work in high temperatures. It can also work in highly acidic and moisture environments. This is provided with no burrs, zero false welding and sharp edge on surfaces. The space tolerance and mechanical strength of this enclosure is extremely laudable. This is specially designed for ensuring optimum protection in filter bags and boosting their service life.

Filter Bag Cage Wire Specifications:

1. Finish: Bright

2. Material: Stainless Steel

3. Grades: 304, 304L, 316, 316L

4. Color: Steel

Superior Material and Build Quality

Our Filter Bag Cage Wire combines stainless steel with an alloy for exceptional strength and corrosion resistance. The galvanized finish not only enhances its appearance but also adds to its durability, making it suitable for harsh industrial conditions.

Versatile Hole Shapes for Optimal Filtration

Choose from round or triangle hole configurations to best suit your dust filtration requirements. These diverse hole shapes provide flexibility for different applications, ensuring efficient airflow and dust capture within your filtration system.

FAQs of Filter Bag Cage Wire:

Q: How does the galvanized surface treatment benefit the Filter Bag Cage Wire?

A: The galvanized surface treatment provides a protective coating that prevents rust and corrosion, thereby extending the life of the stainless steel cage wire and maintaining its silver appearance despite exposure to harsh industrial environments.Q: What are the advantages of using stainless steel with alloy in filter bag cage wires?

A: Stainless steel combined with alloy enhances the cage wires strength, durability, and chemical resistance, making it ideal for long-term industrial use where exposure to corrosive substances and high temperatures may occur.Q: When should you choose between round hole and triangle hole configurations?

A: Round hole configurations are typically preferred for general dust collection, while triangle hole shapes can offer enhanced structural support and allow for higher dust loading capacities. The selection depends on your specific filtration needs and dust volume.Q: Where are these filter bag cage wires commonly used?

A: These cage wires are widely utilized in industrial dust collection systems, such as those found in cement, steel, power plants, pharmaceuticals, and chemical industries, ensuring clean air quality and equipment protection.Q: What is the process of manufacturing a filter bag cage wire?

A: The process involves shaping stainless steel wire with alloy into the desired cage design, followed by surface galvanization for enhanced protection. The wire is then formed with round or triangle holes, cut, and assembled according to precise specifications.Q: How are these cage wires installed and what is their primary usage?

A: They are installed inside filter bags within dust collectors, providing structural support to prevent collapse during operation. Their main usage is to maximize the filtration efficiency and lifespan of filter bags by maintaining optimal airflow and structural integrity.Q: What are the key benefits of using these filter bag cage wires for exporters and suppliers in India?

A: These cage wires offer high export quality, resistance to corrosion, and customizable design options, making them a reliable option for Indian exporters, importers, manufacturers, and suppliers seeking to meet diverse industrial requirements both domestically and globally.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wire for Springs' category

|

PRECISE ALLOYS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese